Injection Molding Manufacturing Capabilities

Quality Mold Shop is able to provide injection moldings with shortened lead times and quality designs that withstand production mold demands. This is accomplished through offices and manufacturing facilities in McMinnville, TN and Kunshan, China with the latest in injection molding manufacturing equipment, computers, and software along with our greatest asset, trained and experienced personnel.

- Design

- Build

- Revise

- Repair

- Prototype and Production Plastic Injection Molds

Injection Mold Capabilities

- Buidling and working with molds up to a weight of 12,000 lbs.

- Capable of producing 100+ Molds per year

Tool Shop Capabilities

Injection Mold Revisions

Our experienced Tooling Engineers make needed mold revisions.

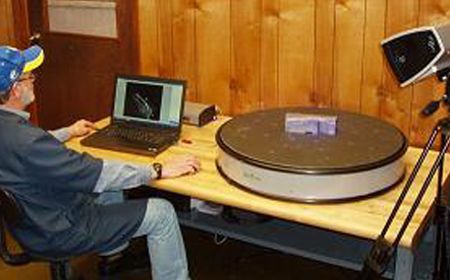

Injection Mold Design

Using the latest in Creo 2, Cimatron, and Solid Works design software.

Injection Mold Build

Our experienced Tool Makers lead the building process.

Injection Mold Presses

From 40 to 400 ton capacity are available for sampling and production runs.

Pickup & Delivery

We can pickup and return up to 12,000 lb. molds.